EPDM extrusion profiles Extrusion, Rubber, Manufacturing

Three EPDM-based masterbatches (M/B) were defined, as shown in Table 1. M/B #B was a factory-scale K2A Intermixer mix used as basis for the extrusion studies. M/B #C was a laboratory mix masterbatch variant used for producing a compound with increased hardness for mechanical property assessment.

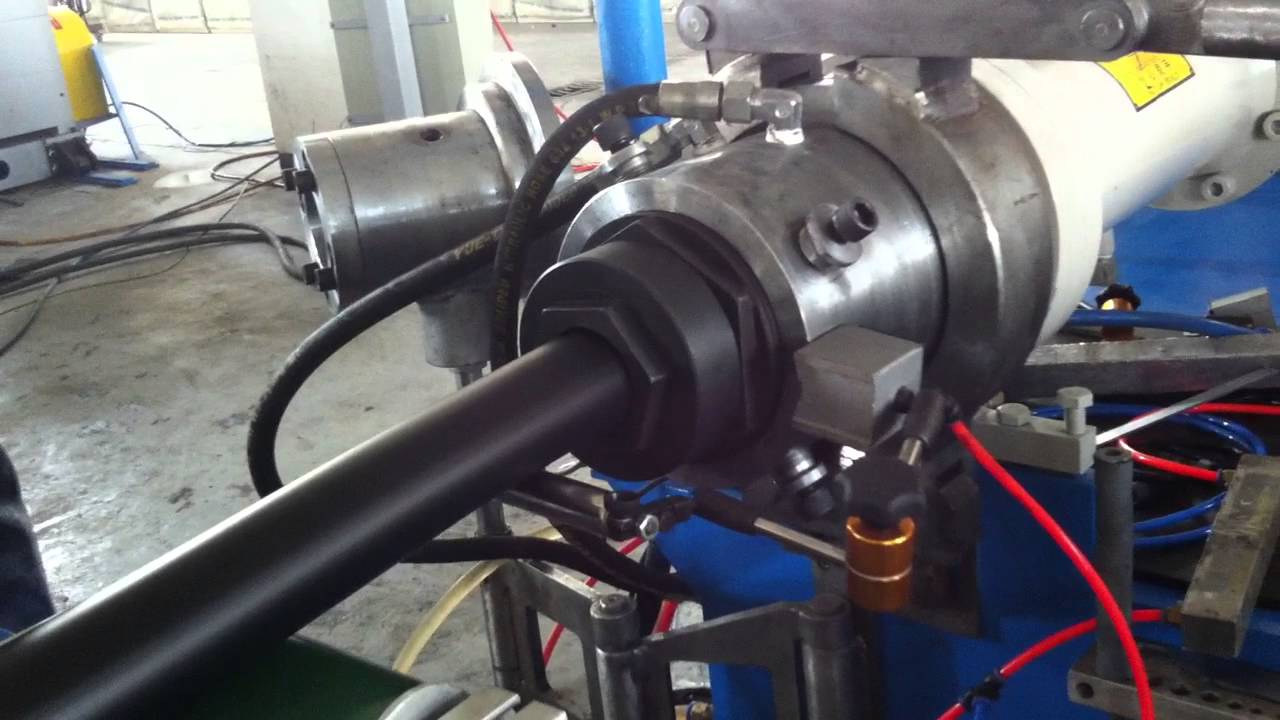

EPDM extrusion extruder machine YouTube

EPDM rubber. As a part of one of the world's largest integrated chemical companies, our Vistalon™ EPDM rubber business requires a focused, long-term approach. We will consistently strive to improve quality, efficiency, and productivity, and are dedicated to empowering our customers to meet society's evolving needs.

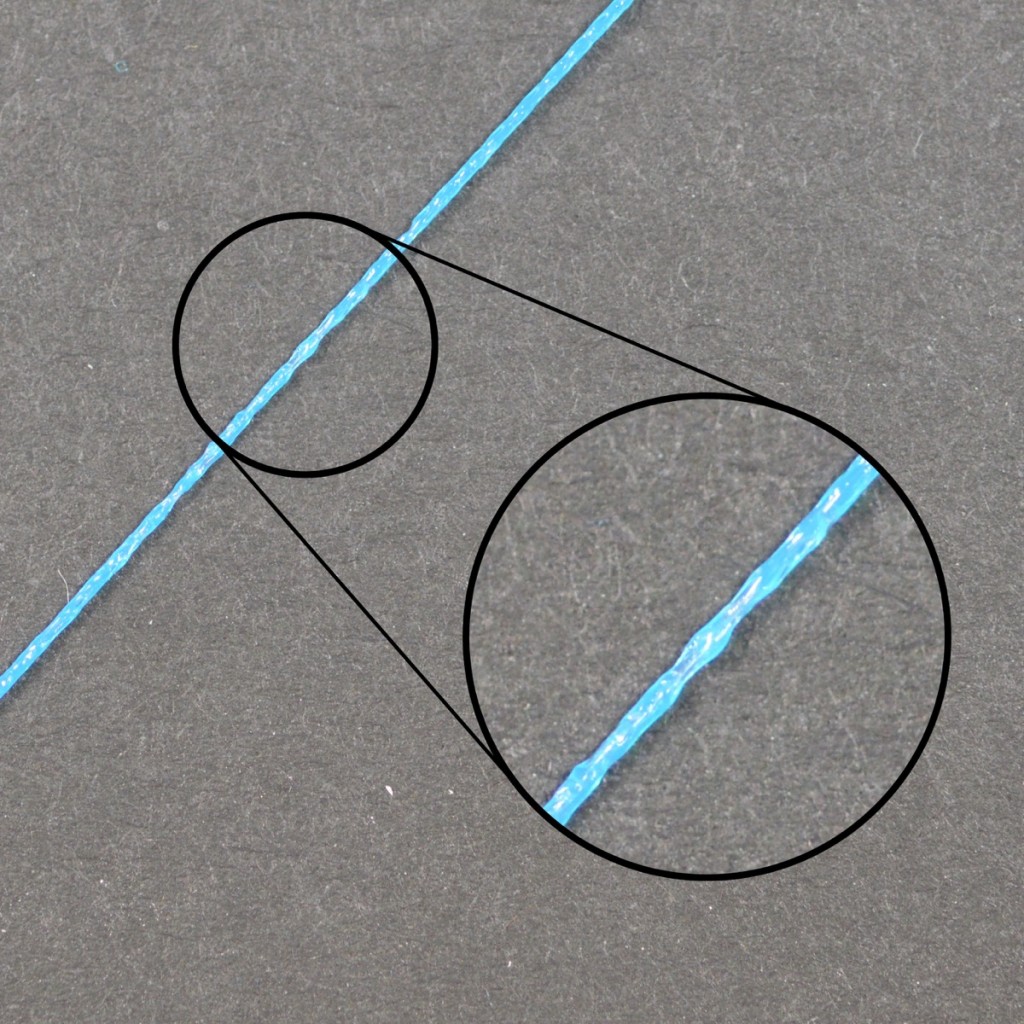

Inconsistent Extrusion

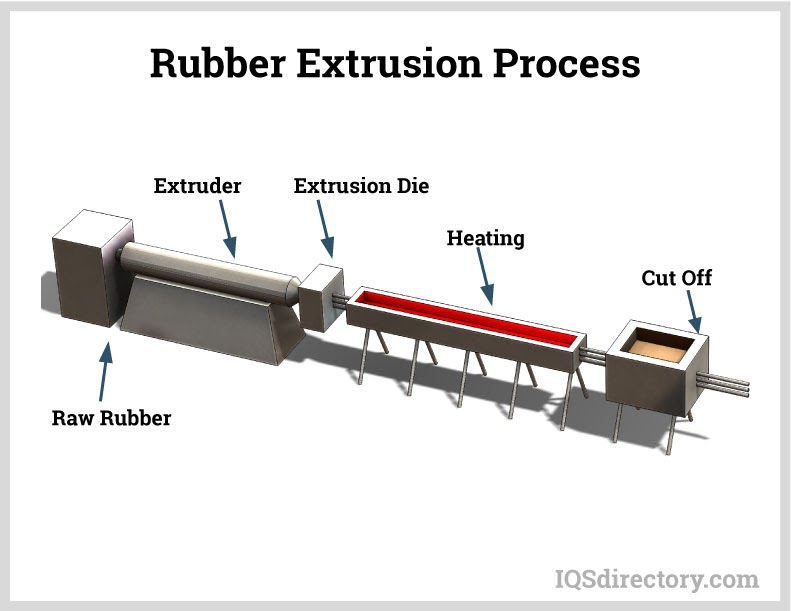

Many low molecular The manufacture of an extruded weight ingredients like process dense profile broadly involves three aids and curatives at low concen-steps: compound mixing; extrusion trations can have high volatility, and shaping; and curing. which can cause porosity.

What is Metal Extrusion, types, and Manufacturing Process

Ethylene-Propylene-Diene-Monomer . TREMPRO ® EPDM Rubber Extrusions are extruded and fabricated into gaskets and accessories for use in sealing and glazing industrial and transportation OEM applications. Tremco rubber extrusions are available in a peroxide formulation for applications in which cure-enhanced memory and rebound characteristics are necessary.

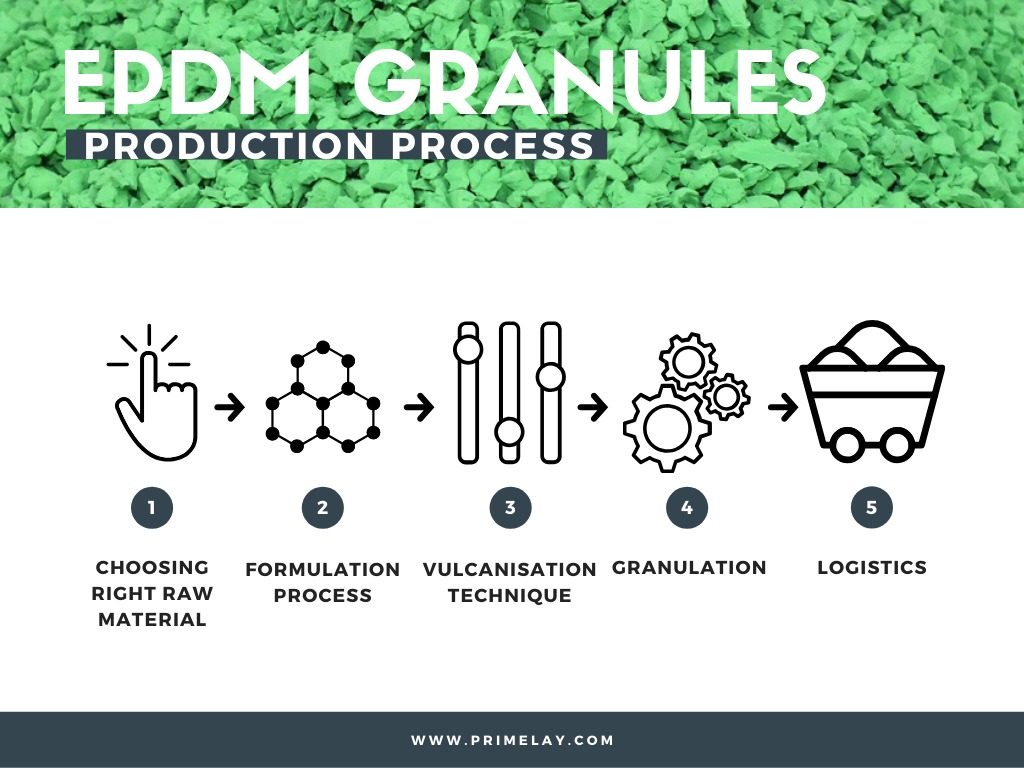

Why EPDM Granules is Important for Seamless Playground Flooring!

At its core, the EPDM extrusion process involves feeding raw EPDM rubber into the extruder, where it undergoes a transformative journey. The rubber is heated, softened, and forced through a specialized die that imparts the desired shape and dimensions to the profile.

EPDM Strip Rubber Extrusion Line , CE ISO9001 Silicone Rubber Extrusion Machine

An extrusion die is a precise and specific tool made by cutting an opening through a blank of steel. The shape of the opening will match the finished rubber cross section desired for an extruded part. Once in place, the rubber material will be forced through this die via the pressure that builds up from the revolving screw of the extruder.

Biologists Discover a Trigger for Cell Extrusion Process for Eliminating Unneeded Cells

Deoflow AP and Deoflow Z--processing additives for EPDM extrusion compounds In general, when mixing and producing EPDM profiles, the processing additives significantly contribute to the viability of these processes and also to the surface finish of the resulting product.

Solid Rubber EPDM Extrusion Profile

Modeling the flow of ethylene propylene diene monomer (EPDM) through a Garvey die was achieved by employing the latest cloud computer technology commercially available at a modest cost. The description of the stress-strain behavior for EPDM was done using the Otswald-de Waele model.

EPDM D Profile Products The Rubber Company

Extruding an EPDM seal works by pushing the rubber compound through an extrusion tool (known as a die). Together with pressure and temperature, the machine extrudes the required shape which is then cured and hardened using a vulcanising line, steam line, salt bath or autoclave cure.

EPDM rubber extrusion Vulcanization production line for fire YouTube

Extrusion is one of the most useful processes for making long rubber product profiles. The profile deforms while extruding due to swelling based on the geometry of the die, thermal and rheological properties of the material, and predominantly on the thermal and rheological boundary conditions.

EPDM Material Learn about EPDM rubber roofing

Ethylene propylene diene terpolymer, or EPDM for short, is a durable material made to withstand the toughest conditions. It can handle high temperatures and abrasive chemicals. Even though it's a tough material, that doesn't mean it has to be tough to work with. Our EPDM products are cleaner, easier to work with and enable efficient manufacturing.

SGS/Rohs standards Construction door window rubber extrusions in black solid density EPDM

The process EPDM rubber production from polymer-grade (PG) propylene and ethylene comprises three major sections: (1) polymerization; (2) purification; and (3) finishing (Figure 2). FIGURE 2. The diagram shows the polymerization process for making EPDM rubber Polymerization.

EPDM extrusion details Extrusion, Manufacturing, Rubber

Go to: Abstract The compounding of waste EPDM from postindustrial scrap with polypropylene (PP) is a possible way to manufacture thermoplastic elastomers to solve a significant environmental problem.

Rubber Tubing What Is It? How Is It Made? Types, Materials

The manufacturing process of EPDM rubber involves three stages; Synthesis, Extrusion or Molding, and Finalizing. During the synthesis stage, ethylene, propylene and butadiene are combined to.

Custom EPDM Extrusion Genesis Rubber Inc.

EPDM is a synthetic elastomer produced as a copolymer of ethylene and propylene, with small amounts of a pendant diene (double bonds) in order to cross link the material. The actual abbreviation EPDM conforms to the ASTM nomenclature guidelines as describing an Ethylene Propylene Diene PolyMethylene main chain elastomer.

EPDM Extrusion at Rs 135/kg Arumbakkam, Ashoka Nagar Chennai ID 9238136562

EPDM is used as a cheaper alternative to silicone rubber for parts that will have a lot of outdoor or moisture exposure, or for electrical insulation. However, it can also be used as roofing or liners. It's mainly used in four industries: Automotive. This is EPDM's most common application, thanks to its flexibility, resiliency, and.